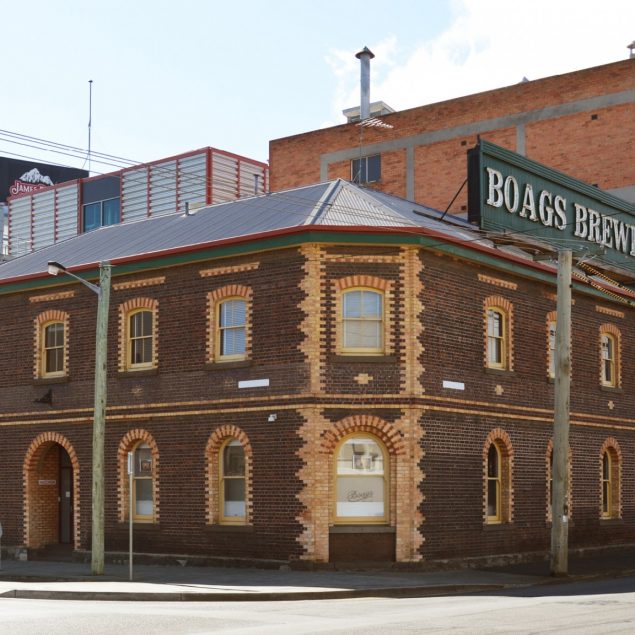

The James Boag Brewery was established on the banks of the North Esk River in Launceston, 1881.

In 2004 the Brewery underwent a major expansion to occupy the block enclosed by William, Tamar and Shield Streets and The Esplanade. In 2007 the Brewery was sold to Lion Co. who now own and operate the Brewery and all associated brands.

In 2016 Lion was approached by TasWater in regards to their James Boag Brewery, to review their existing trade waste discharge agreement. TasWater requested significant changes to this agreement including separation of all current discharge flows. Lion identified that the James Boag Brewery various trade waste streams required significant works to comply with TasWater requirements.

Based on the success of past projects delivered by McMahon Services at Lion’s West End Brewery in Adelaide and the Wetherill Dairy facility in Sydney, Lion selected McMahon Services to co-ordinate, scope, plan, procure and construction manage this project to meet these objectives.

Scope of Work

McMahon Services were engaged to deliver a range of civil and building construction works on site to upgrade the existing trade waste system. A key delivery requirement for all works was that the Brewery remained fully operational throughout the construction period. The project was delivered in three stages:

- Stage 1 involved the separation of the various existing site discharges channels so they are funnelled into either to stormwater, sewer or trade waste systems as appropriate.

- Stage 2 comprised the construction of a buffering infrastructure, a tank farm, various sumps, pumps and associated piping to control the rate of and cool discharge waste, and systems to adjust the pH of the waste accordingly. Various telemetry systems were installed to measure and monitor trade waste flows.

- Stage 3 included the installation and commissioning of a full water treatment system incorporating all aspects delivered in Stage 2.

Associated works to all three stages included building demolition, internal and external excavation, installation of new pipes and sumps, sewer and stormwater tie-ins to TasWater networks both new and existing, construction of a tank bund 50m by 20m that houses the tank farm, construction of the tank plinth that required 26m by 8m deep concrete piles, construction of an enclosed 11m diameter by 8m high stainless steel holding tank, enclosed control dosing tank, tank access staircase, raised steel platform and associated stairs, odour control system, discharge controls, monitoring and water treatment equipment, pumps and piping.