Project Overview

McMahon Services were engaged by Downer to undertake the Unit Asset Replacement at the Para Substation, North of Adelaide.

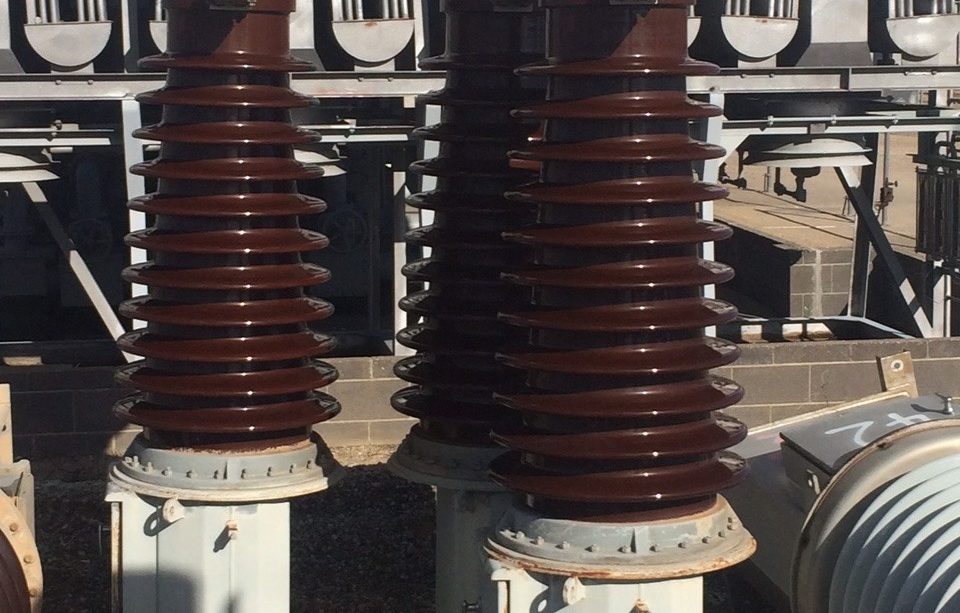

McMahon Services were required to remove and dispose PCB contaminated plant from the substation. Overall works at the Para Substation will replace the entire secondary system and minor primary plant. This includes replacement of 132 kV capacitor voltage transformers, 132 kV and 66 kV surge arresters, protection schemes, control systems and other equipment with new systems that are in accordance with the current ElectraNet design standard.

The project scope included:

- Preparation of EPA permits and transportation permits for the removal and disposal of PCB contaminated plant from site;

- Removal of 29 redundant transformers. The redundant units were removed by crane and high sided tipper, lined with soil to bed the unit down whilst in transit;

- Place transformers within a purpose built bund. The bund can contain up to 3,000 litres of waste oil and has in-built outlets;

- Dismantle units and separate the ceramic and metal waste;

- Drain and flush units into bund;

- Pump waste into Intermediate Bulk Containers (IBC’s) ready for transport;

- Transportation of PCB contaminated plant from the Para Substation to the nominated disposal depot;

- Provide client with a certificate of disposal for each plant.